Real-Time Hazard Detection: How AR Is Making Workplaces Safer

Introduction

If you’ve ever had that heart-stopping moment on a job site—maybe you almost tripped over a stray cable, or you spotted a forklift coming around the corner just in time—you know how quickly things can go from safe to scary. No matter how many safety meetings we attend, or how many checklists we fill out, the reality is: hazards can pop up in an instant.

That’s why I’m genuinely excited about what Augmented Reality (AR) is bringing to the table. It’s not just another tech buzzword—it’s a tool that’s already helping real people, right now, to spot dangers before they become disasters.

What Does AR Look Like on the Job?

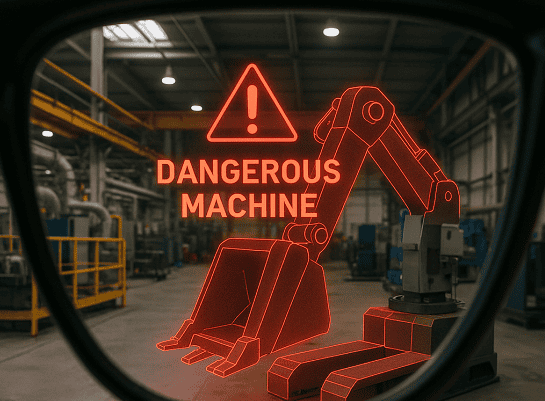

Let me paint a picture: Imagine you’re starting your shift on a construction site. You slip on a pair of AR glasses—think of them as your new “safety sidekick.” As you walk, you see digital alerts hovering over a wet floor, or a gentle reminder to check your harness before climbing. It’s like having a superpower, or at least a really attentive coworker who never gets tired.

The Old Way: Why Traditional Hazard Detection Isn’t Enough

I remember my first week on a job site—clipboard in hand, trying to keep up with the safety checklist while also watching for moving equipment. It was overwhelming! Manual checks are important, but let’s be honest: we’re all human. We get tired, distracted, or just plain miss things.

And those paper checklists? They can’t keep up with a site that changes by the hour. That’s why so many safety managers (myself included) are looking for something more dynamic.

How AR Helps You Spot Hazards—Right When They Happen

So, how does AR actually help? Here’s what I’ve seen in action:

1. Instant Visual Warnings

Picture this: You’re about to step into a restricted area, and your AR glasses flash a bright red warning. It’s saved me (and my coworkers) from more than one close call.

2. Real-Time Updates from Sensors

We once had a situation where a sensor picked up a gas leak in a remote part of the plant. The AR system alerted the nearest worker instantly, and they were able to get out safely. That’s peace of mind you can’t put a price on.

3. Step-by-Step Help When You Need It

I’ve seen new hires get nervous when something goes wrong. With AR, they get clear, step-by-step instructions—no more guessing or panicking.

4. Hands-Free Safety

I love that you don’t have to juggle a phone or clipboard. Your hands are free, your eyes are up, and you’re focused on the job.

Real People, Real Workplaces: AR in Action

On Construction Sites

Construction is full of surprises. I’ll never forget the day AR helped us spot a loose scaffold plank before anyone stepped on it. It’s like having a second set of eyes, always on the lookout.

Image 3:

Worker using AR to spot live wires and restricted zones on a busy site.

In Factories and Plants

One of our clients shared how AR helped them catch an overheating machine before it failed. Maintenance teams can see real-time data and fix problems before they become emergencies.

In Oil & Gas

A friend in the oil industry told me about using AR to guide workers through emergency shutdowns. When seconds count, that kind of guidance can be a lifesaver.

Why Workers and Managers Love AR for Safety

1. You’re Always in the Know

No more surprises—AR keeps you updated with the latest safety info, right when you need it.

2. Faster Reactions

When you see a warning right away, you can act fast—sometimes before a problem even starts.

3. Fewer Mistakes

Clear, visual instructions mean less guesswork and fewer errors, even when you’re tired or new on the job.

4. Better Training for Everyone

We’ve started using AR for training, and it’s a game-changer. New hires can practice handling hazards in a safe, virtual environment before they ever face them for real.

Image 4:

New hires using AR for hands-on safety training in a virtual setting.

5. Smarter Safety Over Time

AR systems track what kinds of hazards pop up most often, how people respond, and where improvements are needed. That means our safety program gets better and smarter every year.

What’s the Catch? Things to Think About

Of course, no technology is perfect. AR gear can be pricey, and it takes time for everyone to get comfortable with new tools. There’s also the question of keeping all that safety data secure.

But as AR becomes more common and affordable, more companies are finding that the benefits far outweigh the challenges.

What’s Next for AR and Workplace Safety?

The future looks bright—and even safer. Imagine AR systems that use AI to predict hazards before they happen, or lightweight glasses that last all day on a single charge. Some companies are even combining AR with drones and robots to inspect hard-to-reach places, giving workers a safer way to spot problems from a distance.

Image 5:

Worker using AR glasses while a drone inspects a high-up area, with data streaming in real time.

Wrapping Up

At the end of the day, we all want to go home safe. AR is helping make that possible by giving workers the tools they need to spot hazards, react quickly, and learn from every close call. As this technology keeps improving, it’s set to become a must-have for any company that takes safety seriously.

Your Turn: Have you tried AR on your job site? Got a story about a close call or a safety win? Share it in the comments—I’d love to hear how technology is making your workplace safer.

Curious about how AR could work at your job site? Reach out to Primus Vision—we’d love to show you what’s possible.

AR Related Curated News

1. Construction Site Fall – April 16, 2025

Source: Technology and Workplace Safety: Innovations Reducing Common Injuries – Mahoney Law Blog, April 16, 2025

A recent blog post highlights the ongoing issue of falls from height in construction, which remain a leading cause of workplace fatalities. In April 2025, a worker in California suffered serious injuries after falling from scaffolding.

Experts noted that AR could have provided real-time alerts about unstable planks or missing guardrails, and VR-based training could have better prepared the worker to recognize and avoid such hazards.

________________________________________

2. Vehicle Intrusion in Road Work Zone – March 2025

Source: Alert modalities in connected and smart work zones to enhance workers’ safety – ScienceDirect, March 2025

A controlled field experiment in March 2025 showed that workers in road construction zones have only about five seconds to react to an oncoming vehicle. In a real incident, a worker was struck by a vehicle that entered a closed lane.

AR smart vests or glasses could have provided immediate visual and audio alerts, giving the worker precious extra seconds to move to safety.

________________________________________

3. Manufacturing Plant Chemical Spill – April 28, 2025

Source: The contribution of Immersive Technologies to Workplace Safety – AR Market, April 28, 2025

A chemical spill in a European manufacturing plant led to several workers being hospitalized.

The incident report suggested that AR overlays could have guided workers to the nearest safe exit and provided real-time hazard information, while VR training could have better prepared them for emergency response.

________________________________________

4. General Workplace Accidents and Missed Hazards

Source: The benefits of augmented reality for workplace safety – World Economic Forum, Nov 24, 2021

While not a single incident, the World Economic Forum notes that nearly 2 million people die from work-related causes each year, with many injuries resulting from missed hazards or lack of situational awareness.

AR could help by overlaying hazard warnings and safety instructions in real time, and VR could provide immersive hazard recognition training.

________________________________________

5. Discussion on Digitalization and Safety – July 23, 2024

Source: The metaverse: how to safely integrate new visualisation technologies in the workplace – EU-OSHA, July 23, 2024

EU-OSHA reviewed how AR and VR can simulate hazardous environments for training, helping workers avoid real-life accidents.

The report references recent accidents in manufacturing and construction that could have been mitigated with better hazard visualization and real-time alerts.

In summary:

Recent workplace accidents—such as falls, vehicle intrusions, and chemical spills—could have been prevented or mitigated with AR and VR technologies.

These tools offer real-time hazard detection, immersive training, and instant guidance, which are increasingly recognized as essential for modern workplace safety.

Recent Comments